|

Wallpaper photo courtesy of Daniel Gross at Pexels.com |

|

Operating principles of the solid-fuel powerplant of the imminent future |

|

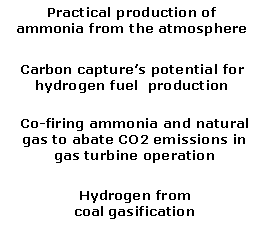

Providers of turnkey plants for the production of: |

|

...and all from waste byproduct CO2! |

|

Carbon-reducing fuel options for thermal power generation facilities |

|

Scholarly works supporting the primacy of co-location when siting power plants and industrial activities in urban areas |